- Easy maintenance – no moving part

- Pre and Medium flitters built-in

- Energy efficient

STANDARD FEATURES

- Double PU skins panel housing

- Direct drive plug fans (Low noise)

- Aluminum Opposed Blade Volume Damper

- Chilled water or Direct expansion

- Copper Coil Aluminum fins

- Aluminum Plate Heat Exchanger

- Stainless steel drain pan

- Built-in Pre & Medium filter

- Easy access for servicing

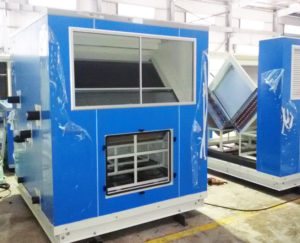

- Compact sizing design (Vertical/Horizontal)

- Start from 500 CFM to 20,000 CFM or more

OPTIONAL FEATURES

- Stainless steel double skin panel

- Coated protective fins – Cooling coil

- Copper fins – Cooling coil

- Stainless steel Plate Heat Exchanger

- HEPA filter

- Modular design

CONTROLLER FEATURES

- Indoor or outdoor (optional) panel cabinet

- VSD control

- PLC controller with SCADA monitoring (optional)

- Inlet and outlet temperature & relative humidity sensors (optional)

How It Works

Our Dehumidifying Air Handler is a mechanical dehumidification concept with using air to air plate heat exchanger equip together with cooling coils in order to condense water vapour in the air at highest efficiency performance.

Plate heat exchanger helps to reduce required capacity of cooling and heating. When cooling coil is smaller and heating coil is not required, cost of accessories and installation is automatically been reduced.

Dehumidification Concepts

There are two types of dehumidification concepts.

- Mechanical dehumidification which is condensed vapor water in the air via cooling surfaces. The result is dry and cool.

- Chemical dehumidification which is absorb vapor water in the air with its chemical characteristic then regenerate (reject wet air) it with hot air to bring back that absorbed ability. The result is dry and hot.